Spray Nozzles

Nozzles are one of the least expensive parts of a sprayer, yet they play a crucial role in its performance. They control the amount of liquid applied per unit area, regulate the spray pattern across the boom width, and determine droplet size, which affects both coverage and spray drift.

At Agrivit, we stock an extensive range of nozzles under each of the following brands:

- ALBUZ

- Teejet

- Arag

- Agrotop

- Hypro

The primary purpose of a nozzle is to break the liquid stream into droplets and create the spray jet. Agricultural spray nozzles come in several types, including:

- Turbulence nozzles: Create conical, solid, or hollow spray patterns.

- Flat fan nozzles: Also available in twin fan designs.

- Discs and cores: Combine to produce a range of conical, full, or hollow jets, offering varied flow rates.

- Metering discs: Used to calibrate flow rates, either on their own in pneumatic sprayers or with other components in air blast systems.

Choosing the right nozzle can be challenging but is critical for effective application. We are well equipped to help you pick the right nozzle, but here are some tips to help you if you’re selecting one on your own:

Key Nozzle Characteristics

When selecting a nozzle, consider the following:

- Size: Flow rate in litres per minute at standardised pressure.

- Angle: Most common angles are 80° and 110°.

- Material: Options include ceramic, plastic, stainless steel, and brass. Ceramic is the most durable, especially for high-pressure applications, hard water, or abrasive mixtures.

- Spray Pattern: Common types are flat fan and hollow cone, with other options like twin fan and off-centered patterns available.

- Operating Mode: Nozzles have evolved to enhance spray quality and minimise drift, including standard, drift-reducing, and air-injection designs.

- Working Pressure Range: Each nozzle has an optimal pressure range for peak performance.

- Droplet Size: Tailor the droplet size to the crop, pest, or growth stage. Nozzle charts provide droplet size classifications by pressure, helping you choose the most suitable option.

Selecting the correct nozzle for the task ensures better efficiency and improved results in crop protection and spraying applications.

The choice should be guided by different parameters:

- The volume to be applied per unit area. Most often expressed in litres per hectare

- The desired working speed, expressed in km/h.

- The spacing between the nozzles, expressed in meters.

- The most common being 50 cm (or 0.5 m).

Nozzle Testing

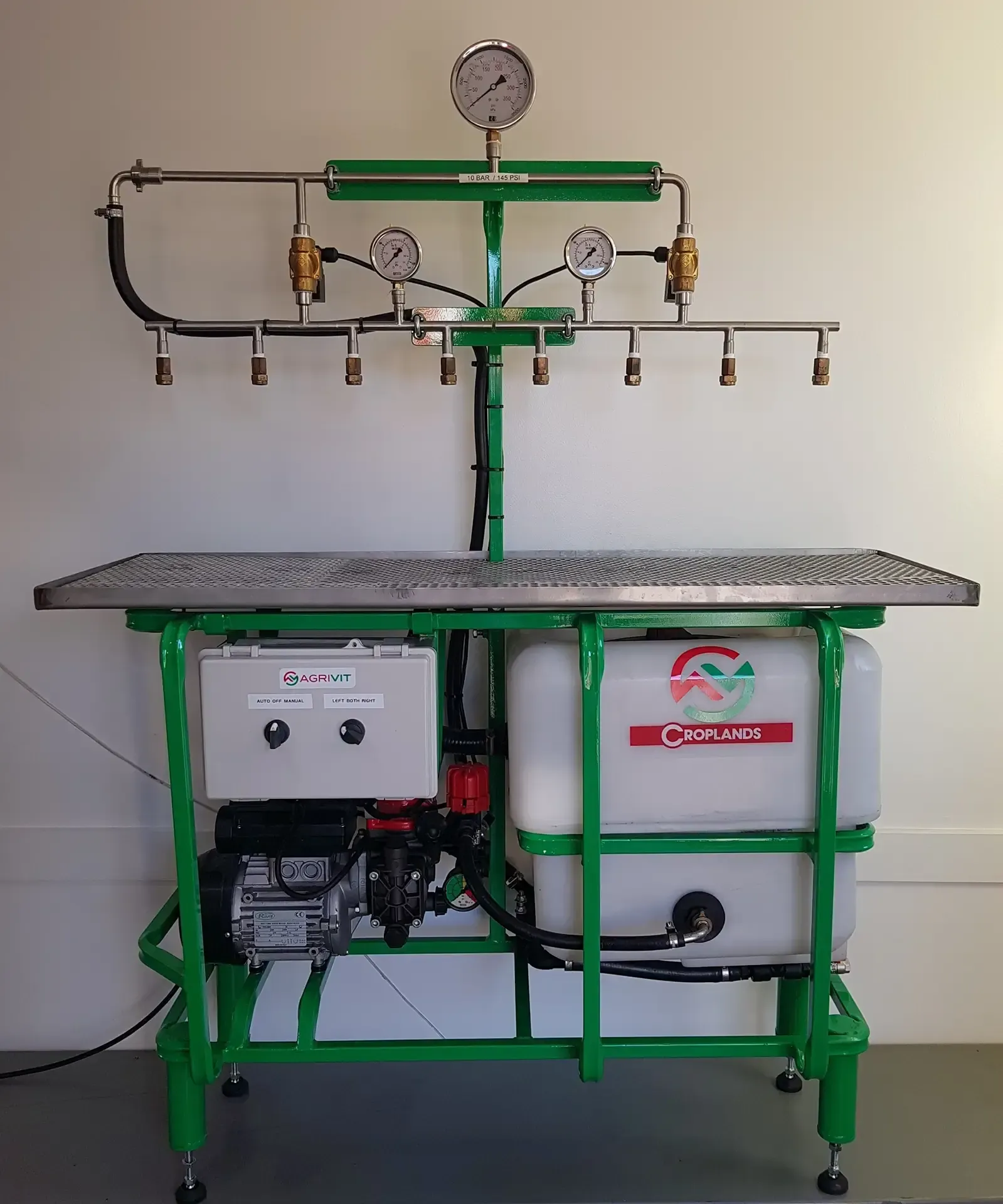

Coverage is king when it comes to canopy and crop spraying, so in 2019 Agrivit conceptualised, designed and built New Zealand’s first testing facility for vineyard sprayer nozzles. The technology ensures vineyard operators are able to achieve precision spray results for their crops, using the ideal volume of product, and only replacing expensive nozzles as and when required.

The testing programme sees beyond the nozzle surface and precisely measures each nozzle's spray functionality. Sprayers utilise a variety of nozzle types and each carries a different recommended spray rating and replacement timeline. Our nozzle testing machine bypasses this confusion and by testing each nozzle's individual flow rate, we can produce a report clearly identifying which nozzles are in need of replacement.

Identifying those that are not running efficiently allows you to replace only those in need of replacing, providing a cost effective way to ensure that you get optimum spray coverage.

If you need help picking or testing your sprayer nozzles, call in and see us or give us a call today.